Resolving Code 3087371: Right Hopper Solenoid

Introduction

The diagnostic code 3087371 is crucial for the Right Hopper Raise Solenoid. Abnormal voltage in the solenoid circuit can cause a loud buzzing sound and prevent the RH Operator ECM from functioning correctly, leading to operational problems. Understanding the cause of this code and how to fix it helps in scheduling maintenance and preventing issues from worsening. In this article, we will explain all the actions, from identifying the issue to implementing corrective measures.

Suppose you are in a critical surgical procedure, and then everything comes to a standstill because of a new code that you did not recognize. This is one situation that no operator wishes to go through, yet it is becoming increasingly rampant. Therefore, understanding the 3087371 code, its meaning, and ways of dealing with the issue can only prove beneficial in saving time and money. Now that we know what leads to this code, let’s explore how you can easily fix it.

The 3087371 diagnostic code targets the Right Hopper Raise Solenoid as it deals specifically with management of voltage. If the right light activates, the right hopper ascends to its highest level, and the fault lamp on the operator station illuminates. This condition usually arise from the solenoid’s energize circuit or in very few occasions a faulty ECM. It is important to visually also check all the harness connectors in a circuit before proceeding with the repair work as the may be dirty or they may not be well plugged in.

Understanding the Right Hopper Raise Solenoid

The Right Hopper Raise Solenoid plays a significant role in controlling the functions of the hopper. When it functions properly, it helps the hopper move smoothly and maintain its correct position, which is 22. The regulator’s operation and its interaction with the solenoid valve are subject to many conditions that can cause interference. Even a small AC voltage ripple in the solenoid circuit can trigger diagnostic code 3087371. Therefore, you should identify symptoms early to prevent losses and ensure the machines’ efficiency.

Common Causes of Diagnostic Code 3087371

Therefore, it is possible to identify several reasons for obtaining the 3087371 code. The most recurrent issue is that short circuit in the energizing circuit, perhaps connecting with another potential. However, as can also be deduced from the list, this code is also associated with an ECM failure, although the chances of this happening are rare. These poor connections are perhaps one of the most typical and/or neglected causes of electrical issues. Another area is the connectors and other problems that may be likely to occur with the harness; it is convenient to record them during inspection.

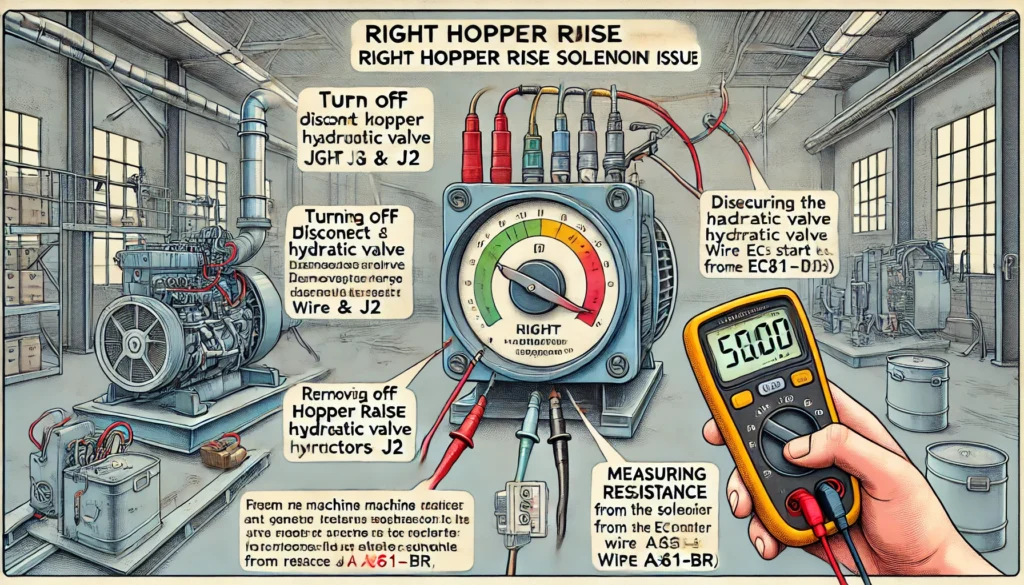

Step-by-Step Diagnostic Process

To diagnose the problem accurately, follow these steps: Here are the steps to follow, if you want a correct diagnosis of the problem.

. Rotate off the disconnect and key start switches on the generator.

. Remove Hopper Raise hydraulic valve and ECM connectors J1 & J2 from the machine harness and then disconnect the electrical connection hose of the machine harness at solenoid.

. The current requirements hence need to be taken from other contact points of the ECM connectors in cores J2-3, wire A861-BR.

. If the resistance is more than 5000 ohms there is no short circuit. If it is less, there is a short which has to be rectified; otherwise, there is no problem.

Inspecting and Repairing Harness Connectors

According to the accessible information regarding electrical troubles, Harness connectors are often the very first connectors to concentrate on during diagnosis procedures. Ensure that all points are shiny and non-corroded also make sure that are well tightened on their respective connection. If you find any of the connections are bad, then rebuild that or get a better connection before proceeding any further. In this case, one can undertake routine check-ups on the machinery without necessarily waiting for a breakdown; this can help avoid the attainment of the 3087371 code and greatly prolong the life of the machinery.

Testing ECM Functionality

To verify the ECM’s function without shorts, turn off the disconnect and key start switches, and remove the solenoid energize wire A861-BR from the ECM receptacle. After that connect all the wires of the harness connectors and then switch on the aforementioned switches. If CID 2553 FMI 03 code is not visible and CID 2553 FMI 05 shows, this sufficiently indicates that the ECM is working properly and the issues are with some other components.

FAQ’s

What is the Right Hopper Raise Solenoid?

It’s a component controlling the hopper’s movement in machinery.

What does diagnostic code 3087371 indicate?

It indicates an abnormal voltage in the solenoid circuit.

How can I fix the 3087371 code issue?

Inspect for shorts and faulty connections; test the ECM if needed.

Can ECM failure cause the 3087371 code?

Yes, but it is a less likely cause compared to circuit issues.

What should I check first when troubleshooting this code?

Start by inspecting harness connectors for any connection issues.

Conclusion

Thus, in order to advance to the problem related to the diagnostic code 3087371 within the process of work, it is essential to provide for the methodical approach to the problems’ examination to ensure their integral identification and potential solutions. Hence, through this article, people with a Right Hopper Raise Solenoid and those concerned with the situations that make the aforementioned code operational are in a position to handle their equipment. Therefore, you should perform regular checks and maintenance measures to prevent the occurrence of such diagnoses while working with minimal interruptions and downtime. Thus, we are able to observe and manage all the challenges concerning this diagnostic code in order to improve effectiveness within the healthcare system.